The clean hydrogen energy economy was a dream. The climate bill could make it a reality this decade

A tax credit tucked into the Inflation Reduction Act has the potential to make the cost of clean hydrogen comparable to that of conventional hydrogen.

A sign for a hydrogen fuel pump at a train refueling station in Germany. Hydrogen has a diverse range of applications and can be used in a number of industries.

Krisztian Bocsi | Bloomberg | Getty Images

A tax credit tucked into Inflation Reduction Act could turbocharge the nascent clean hydrogen industry and turn it into a multitrillion-dollar business in the coming decades.

The tax credit will spur hydrogen producers to develop cleaner ways to synthesize hydrogen, which is used to make fertilizer and in other industrial processes. But it could also catalyze a whole new category of companies looking to use clean hydrogen as a replacement for fossil fuels in areas such as shipping, aviation, heavy industry, and as a way to store and transport energy.

Currently, 98 percent of hydrogen is made in a way that uses fossil fuels, according to the Center on Global Energy Policy at Columbia University. But "all the current hydrogen producers are looking to produce clean hydrogen," explained Elina Teplinsky, a lawyer who serves as the spokesperson for the Nuclear Hydrogen Initiative, a group working to advance the development of the nuclear hydrogen industry.

The law will make it more economically feasible to use carbon capture and storage technology to reduce the carbon emissions from hydrogen creation. It will also open the door to a whole range of companies looking for cleaner ways to make hydrogen, and to use hydrogen as a replacement for fossil fuels in certain areas.

By 2050, between 60 and 80 percent of hydrogen production will be powered by renewables, according to a November report on the industry published by the Hydrogen Council, an industry group, in collaboration with McKinsey & Co. (This prediction was published before the tax credit was passed.)

This kind of industry transition will require a lot of investment — as much as $7 trillion to $8 trillion through 2050. But on the plus side, by that date the hydrogen economy could generate about $3 trillion in annual revenue, according to the Hydrogen Council and McKinsey report.

What is hydrogen used for today, and how could it fight climate change?

Currently, roughly half of the hydrogen produced is used to make fertilizer and ammonia, with the balance used in petrochemical refineries or production, according to the Center on Global Energy Policy. The push for clean hydrogen is motivated both by a need to decarbonize current processes and because the use cases for hydrogen are expanding.

Industrial applications, which make up nearly all the demand for hydrogen today, will represent only 15% of total hydrogen demand by 2050, according to the Hydrogen Council/McKinsey report.

Hydrogen has the highest energy per mass of any fuel and does not release any carbon emissions when it is burned or turned to electricity in a fuel cell. Entrepreneurs and advocates believe hydrogen could be useful to decarbonize some very large sectors of the economy like long-haul trucking and industrial processes including making iron and steel, maritime cargo shipping, and aviation.

"If it weren't for climate change, we probably wouldn't be expanding into all of these new use cases" for hydrogen, Emily Kent, the U.S. director of zero-carbon fuels at Clean Air Task Force, a global climate nonprofit, told CNBC.

The largest end use for hydrogen by 2050 is expected to be mobility, including heavy trucking, long-range flights and container ships, according to the Hydrogen Council/McKinsey report. In these cases, hydrogen would produce electricity through a fuel cell, in which hydrogen atoms and oxygen atoms are combined in an electrochemical reaction to generate electricity, heat and water.

Current electric battery-powered vehicles can't meet this need because batteries that could store enough energy for long-haul journeys would be too heavy and would take too long to recharge, Kent explained. A hydrogen tank and fuel cell would weigh less, take up less space and have the refueling time similar to gas or diesel.

"It's possible that there'll be huge breakthroughs and batteries or something else that would change things. But as it stands today, there aren't great solutions," Kent told CNBC.

Digital generated image of wind turbines, solar panels and Hydrogen containers standing on landscape against blue sky.

Andriy Onufriyenko | Moment | Getty Images

Hydrogen can also be burned to produce electricity in a turbine, similar to natural gas. Currently, up to 20% hydrogen can be blended with natural gas burned in conventional natural gas turbines without needing to do any infrastructure changes, according to Kent.

"For higher blends of hydrogen or pure hydrogen, we'll likely need adjustments to the turbines and infrastructure," Kent told CNBC. "There are companies working on 100% hydrogen-ready infrastructure where pure hydrogen can be burned in a turbine to produce electricity."

Hydrogen can be a way to store energy, which is going to be critical as renewable energy like wind and solar are ramped up and deployed across the country. Wind and solar energy don't work when the wind doesn't blow or the sun doesn't shine, and so energy has to be stored somehow to be able to provide continuous, reliable energy. Meanwhile, battery technology is being ramped up, but batteries are not yet at the point in their development where they can store enough energy for long enough to make them sufficient backup for a fully renewable grid.

"If you produce a ton of solar in the summer, and you want to store a bunch of it away for the winter, hydrogen can be stored for sort of that many monthslong seasonal periods, and provide electricity back to the system when it's needed," Kent said.

Cleanly produced hydrogen is also being considered as a replacement for coking coal in a key part of the process in producing steel, a heavy-emissions industry which is considered a real challenge to decarbonize. And clean hydrogen will be needed for industrial processes that require especially high-grade heat, temperatures above 752 degrees Fahrenheit, like cement plants, glassmaking, and aluminum remelting, according to the Hydrogen Council/McKinsey report.

What is clean hydrogen?

Hydrogen is the most abundant element in the universe, but here on Earth, it only exists in compound forms with other elements — particularly with oxygen as part of water. Separating the hydrogen from the other atoms requires industrial processes and energy.

Currently, China is the largest producer of hydrogen, according to the Center for Strategic and International Studies (CSIS), a bipartisan, nonprofit policy research organization. Of the hydrogen that China makes, 60 percent is made using coal and about 25 percent comes from using natural gas, according to CSIS. Outside of China, the largest hydrogen producers are industrial gas companies like Linde and AirProducts, according to Teplinsky.

Seventy-six percent of hydrogen produced globally and 95% in the U.S. is produced with a process called steam methane reforming, in which a source of methane, like natural gas, reacts with steam at very high temperatures, according to the Center on Global Energy Policy. Natural gas releases greenhouse gas emissions when burned, and also from so-called fugitive methane leaks as it's extracted and transported.

Globally, 22% (and 4% in the U.S.) is made with a process called coal gasification, where coal reacts with oxygen and steam in hot temperature and high pressure.

19 August 2021, Schleswig-Holstein, Geesthacht: Notes on the splitting of water into hydrogen and oxygen can be seen in a laboratory at the Helmholtz Centre hereon in Geesthacht. The Cluster Agency Renewable Energies Hamburg (EEHH) provided information on current developments in the topic as part of a media trip. Photo: Christian Charisius/dpa

Picture Alliance | Picture Alliance | Getty Images

Some companies are working to capture the carbon dioxide emissions from these processes and store it in tanks underground. Hydrogen made this way is sometimes called "blue hydrogen."

More promisingly from an emissions perspective, an electrolyzer can be used to split a water molecule into hydrogen and oxygen, and it can be powered with almost any energy source — including zero-emissions sources like solar or wind, creating what is known as "green hydrogen."

Today, two percent of the hydrogen made globally and 1 percent in the U.S. is made with an electrolyzer.

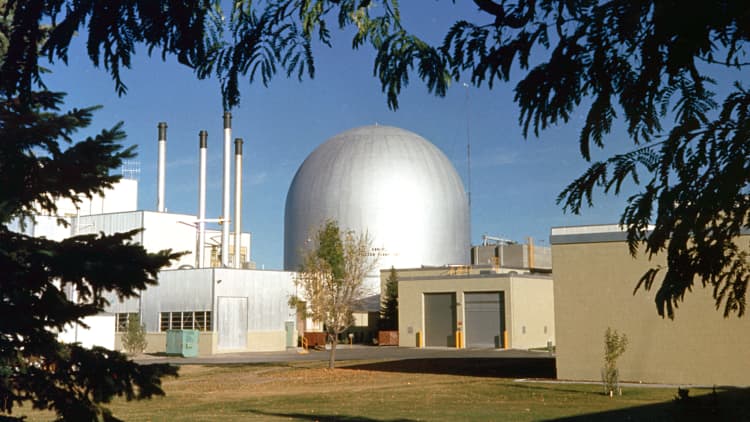

Nuclear energy can also be used to power hydrogen synthesis with almost no additional CO2 emissions (this is sometimes called "pink hydrogen," but the nomenclature varies). As a bonus, the steam and heat produced as byproducts of nuclear energy can be used in a high temperature electrolysis process, which is much more efficient. And with the advanced nuclear reactors in development that run at even hotter temperatures than conventional nuclear reactors, hydrogen can be produced in a thermo-chemical water-splitting process that doesn't use an electrolyzer at all.

Because the majority of the cost of producing hydrogen with electrolysis is the cost of the electricity that goes into it, making hydrogen with nuclear energy and steam "really could have a tremendous contribution on lowering the costs of clean hydrogen production," Teplinsky told CNBC.

The cost of producing hydrogen with these different methods varies tremendously and swings based on input costs, like natural gas and the source of power. Because of the Russian war in Ukraine and climate change, these input costs have themselves been swinging. A report published by nonpartisan nonprofit Resources for the Future in December 2020 said a kilogram of hydrogen made with steam methane reforming cost between $1 and $2 (including the costs of some carbon capture). Hydrogen made with electrolysis powered by wind and solar ranged from between $3 and $7 per kilogram.

That's where the tax credit comes in.

How does the new bill help?

The tax credit in the IRA is available for 10 years and scales depending on how clean the hydrogen production is. If hydrogen is produced without releasing any carbon emissions, the tax credit is maxed out at $3 per kilogram of hydrogen produced. It then scales down proportionally based on the amount of emissions released, as long as it's less than current production techniques.

If hydrogen is produced with some carbon emissions, but fewer than are emitted in current production techniques, the tax credit is incrementally smaller, proportional to the emissions reductions.

The tax credit is "an absolute game-changer," Akshay Honnatti, the leader of EY's sustainability tax division for the United States, told CNBC. "There was no incentive to have hydrogen be cleaner. It costs to get hydrogen to be cleaner," Honnatti added. "Now there's a credit available for someone to make that additional level of investment and be able to justify that level of investment to their stakeholders and shareholders."

The $3 per kilogram credit makes nuclear hydrogen highly competitive with fossil fuel produced hydrogen, Teplinsky said. The U.S. Department of Energy has as a goal, one of its Energy Earthshots Initiatives, to reduce the cost of clean hydrogen to $1 per kilogram in a decade.

For many of these burgeoning use cases for clean hydrogen, the tax credit included in the climate bill is going to give companies the chance to enter the market for making clean hydrogen without losing money. "They could go back to their shareholders, and they can say, 'Look, we can we can do this economically — today. We don't have to project a loss for the next five years to enter this market. We can actually enter this and have it be economic, or at least a breakeven project in the near future,'" Teplinsky said.

The Bipartisan Infrastructure Law passed in November also included $8 billion to develop regional clean hydrogen hubs in the U.S. Between the two laws, the U.S. should be able to develop a clean hydrogen economy in seven to eight years, Teplinsky said.

KickT

KickT