He failed 5,126 times, but now runs a multibillion-dollar biz: We interviewed THE James Dyson

Hairdryers, vacuums, air purifiers—for most people, Dyson is synonymous with high-end household appliances. But the company has always seen itself differently; not as an appliance brand, but as a technology company, driven by a relentless pursuit of solving problems...

Hairdryers, vacuums, air purifiers—for most people, Dyson is synonymous with high-end household appliances.

But the company has always seen itself differently; not as an appliance brand, but as a technology company, driven by a relentless pursuit of solving problems others overlook.

After all, it was this very obsession that transformed James Dyson’s one-man operation into a multibillion-dollar global powerhouse.

We had the rare opportunity to visit Dyson’s global headquarters, tour their cutting-edge Singapore Advanced Manufacturing site, and speak with the man behind it all to uncover how the company’s focus on problem-solving and innovation fuels its success.

The “heart” of Dyson’s creations

James Dyson’s journey began with a simple frustration: in the late 1970s, his traditional vacuum cleaner’s performance steadily declined as its bags clogged, choking suction power.

Vacuum cleaners from the 1970s used to look like this./ Image Credit: Martin Bergsma/ Shutterstock.com

Vacuum cleaners from the 1970s used to look like this./ Image Credit: Martin Bergsma/ Shutterstock.comRecalling an industrial cyclone separator he had seen years earlier, he set out to reinvent the vacuum cleaner by removing the bag altogether. After five years, 5,126 failed prototypes, and countless hours in his workshop, James Dyson finally cracked the code.

The result wasn’t just a better vacuum—it was a blueprint for how the company would approach every product, from that point on.

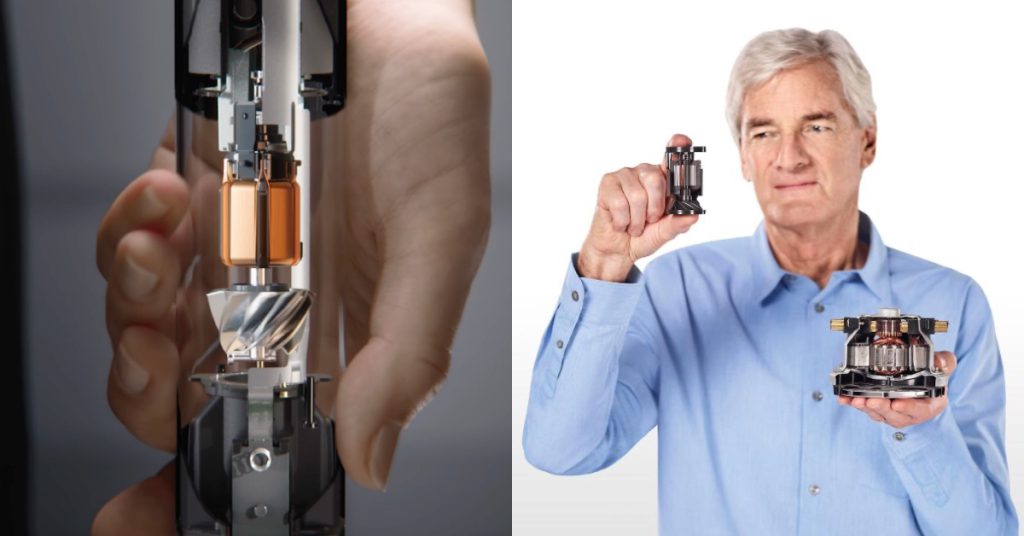

Image Credit: Dyson

Image Credit: DysonAt the heart of every one of Dyson’s innovations lies its digital motors, a technological breakthrough that powers their appliances and continues to drive the company’s evolution.

The latest version, which drives Dyson’s newly launched PencilVac, is the company’s smallest and lightest yet—but also its fastest. It spins at an astonishing 140,000 revolutions per minute (rpm), and that’s faster than a Formula One engine.

A Formula One engine is 16,000 rpm, and a Rolls-Royce jet engine is about 15,000 rpm—no one has ever made a motor get anything like this fast before.

James DysonBut achieving this level of performance demands precision engineering at the microscopic level.

Motors spinning at such extreme speeds generate immense forces, and if the rotor is even slightly off-balance, it can create lateral forces of up to 30 tonnes. Additionally, heat, vibration, and air resistance all need to be accounted for and minimised.

That’s why these motors are built not by human hands, but by robots in Singapore.

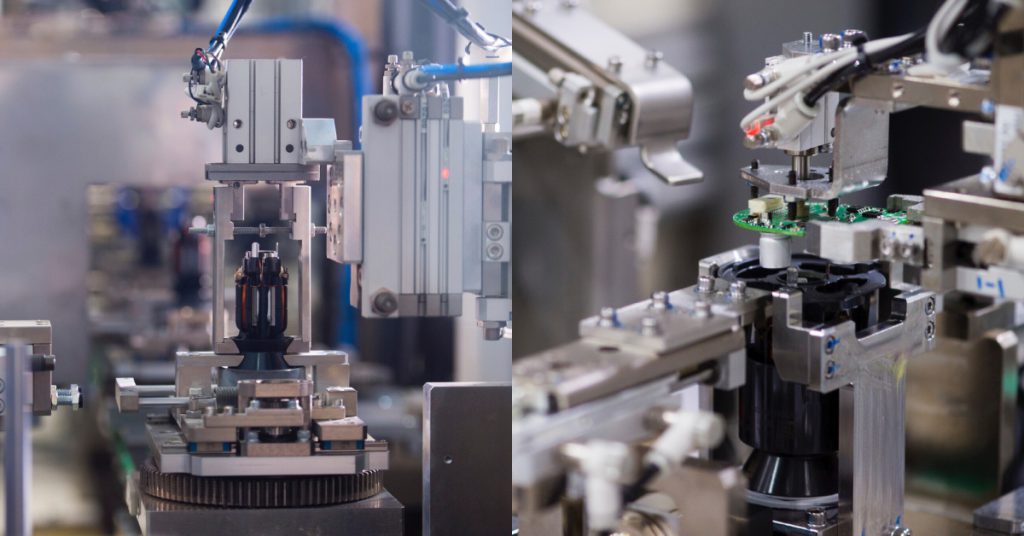

Image Credit: Dyson

Image Credit: DysonInside Dyson’s Singapore Advanced Manufacturing facility at Pioneer Crescent, over 400 autonomous robots work around the clock, monitored by the company’s skilled engineers and technicians.

The production line is a feat of mechanical choreography: arms twist, wind, and insert components with precise timing.

Image Credit: Dyson

Image Credit: DysonWe watched as ultra-thin copper wires—just 90 microns thick, roughly the width of a human hair—were meticulously wound around iron cores. Nearby, other machines fused the motor’s components together.

Quality checks are also built into every step. One machine uses vision technology to inspect the winding of the copper wires, measuring their height to detect even the slightest variation, while another tests the bond strength of fused components to ensure structural integrity.

All this happens at remarkable speed—these robots are capable of producing one motor every two seconds, and to date, have manufactured more than 100 million digital motors in Singapore alone.

But of course, nothing is ever 100% perfect.

At the site, an engineer acknowledged that while a small number of motors may not meet internal standards during production, the fallout rate remains impressively low, thanks to the precision of these robots. Those that don’t meet the strict criteria are identified and filtered out before reaching consumers.

Success attracts imitators

With these technologies in place, Dyson prides itself on the quality and engineering behind every product—a reputation that has helped it stand out.

But success, inevitably, attracts imitators.

While Dyson may have pioneered many of the breakthroughs in cordless vacuum cleaners, bladeless fans, and high-speed hair dryers, the market has become increasingly crowded in recent years.

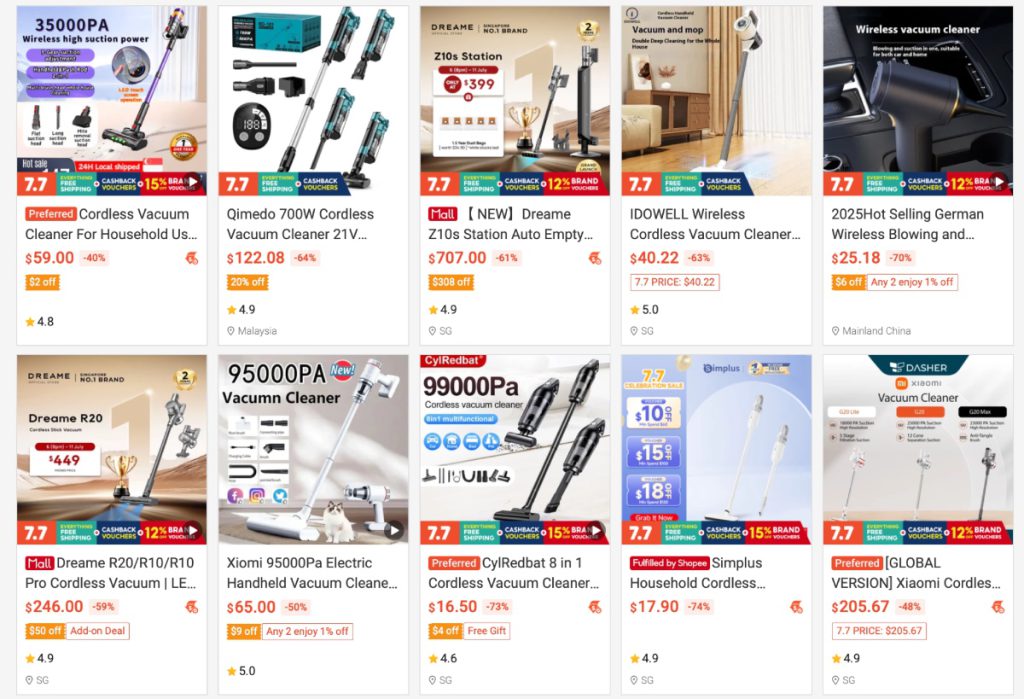

Just take a look at e-commerce platforms like Shoppee and Lazada—a quick scroll would reveal that there is no shortage of lookalikes at a fraction of Dyson’s prices.

At a media roundtable, James Dyson didn’t mince words when asked how he felt about the rise of copycats.

“I’m really worried about them,” he said. “Patents give you some protection, but they don’t actually stop someone infringing the patent. What you then have to do is to sue the person—and I’m afraid it happens quite a lot, and we have quite a big legal department.”

Yet, there’s a difference—and it’s one that might continue to set the company apart.

Although Dyson’s products come with a premium price tag, they’re built to last. Copycat versions, on the other hand, often start to falter far sooner—a trade-off that will ultimately cost consumers more in the long run.

Solving problems that others ignore

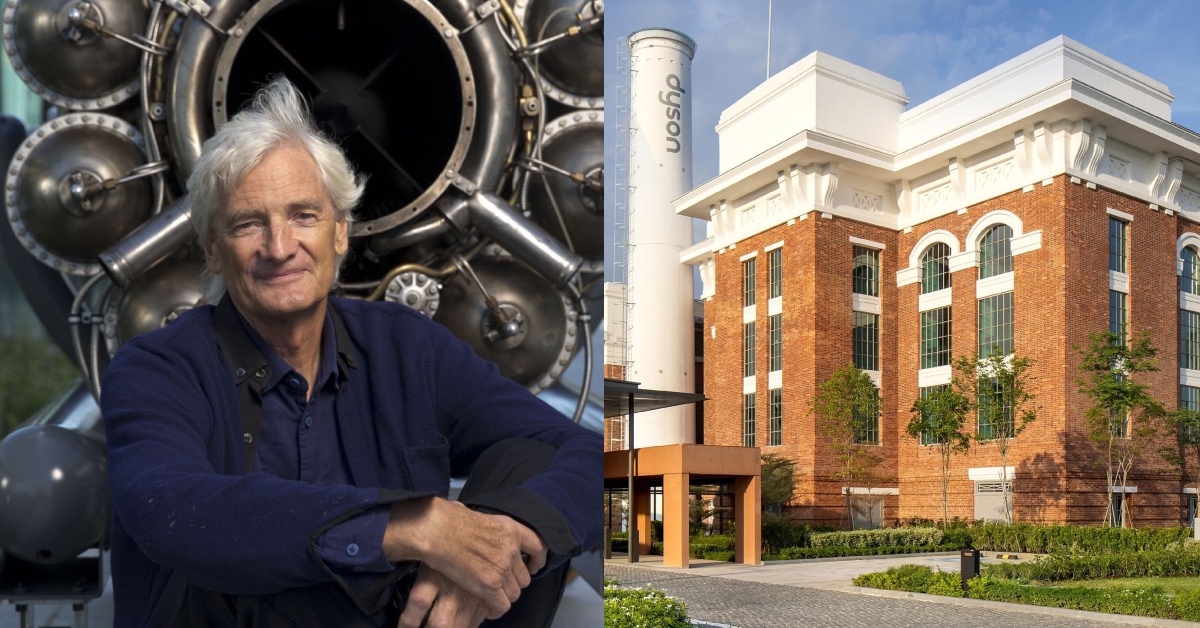

James Dyson and the company’s latest vacuum cleaner, the PencilVac./ Image Credit: Dyson

James Dyson and the company’s latest vacuum cleaner, the PencilVac./ Image Credit: DysonJames Dyson first registered his business in 1991—and 34 years on, he’s still actively involved with running the company. Now 78, the British inventor shows no signs of slowing down.

In 2022, Dyson completed the relocation of its global headquarters to Singapore, a strategic move that reflected the company’s long-term view of where the future lies.

Dyson’s global headquarters at the St James Power Station./ Image Credit: Dyson

Dyson’s global headquarters at the St James Power Station./ Image Credit: Dyson“We realised the importance of the Asian market,” he said. “[But] we were British… and we wouldn’t understand the Asian market properly and wouldn’t be in the correct geography to satisfy it, unless we were here.”

Singapore, he added, offered a compelling base: not just for its location at the heart of Asia, but for its deep talent pool of engineers and a supportive ecosystem for innovation and manufacturing.

Leveraging this strategic position, the company plans to continue scaling its operations and developing new technologies.

Though Mr. Dyson remained tight-lipped about what’s next, he did offer a glimpse into his mindset when it comes to inventing new products—and the uncertainty that comes with it.

You can’t guarantee that a new product would be successful. And that’s what makes it exciting… it’s like a form of gambling. I never want to be a gambler, but I do gamble with products.

I didn’t know whether people wanted a vacuum cleaner without bags. All you can hope is that people think in the same way that you do.

James DysonWhen asked if, in the constant pursuit of solving problems, he ever worries about not having enough time and resources to fix them all, he offered a reflective answer:

“It’s a bit like planting trees,” he said. “I plant trees now, I’ll never see them grow fully in my lifetime, but it doesn’t mean I shouldn’t do it. I’m doing it for other people.”

In many ways, that mindset encapsulates the ethos behind Dyson’s decades-long journey. Because at Dyson, its mission has always remained the same: to solve the problems that others ignore.

Read other articles we’ve written on Singaporean startups here.Featured Image Credit: Dyson

Aliver

Aliver

.jpeg?width=1200&height=800&crop=1200:800)